| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | YUTAI |

| Model Number : | H62 H65 H80 H90 |

| Certification : | ASTM JIS GB AISI |

| Price : | Customized |

| Payment Terms : | T/T, L/C, Western Union |

| Supply Ability : | 1000 ton/month |

| Delivery Time : | 5-15 days |

Description

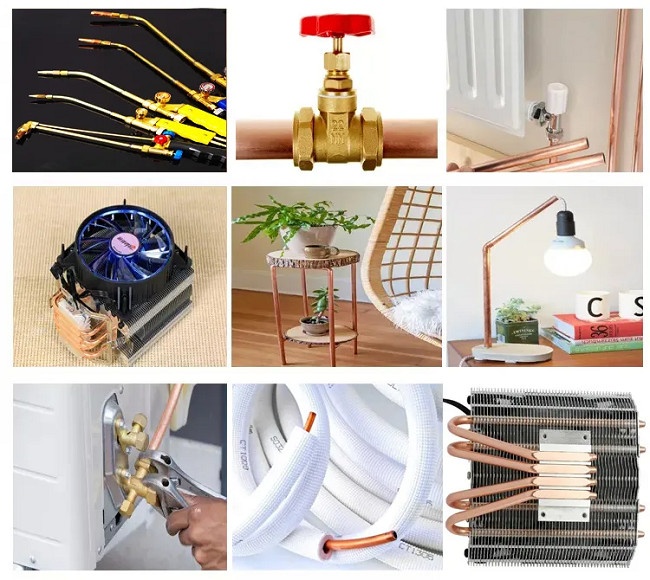

Copper tubing is the ideal material for many applications. Its

strength, the ease with which it is fabricated and soldered, and

its high conductivity to heat is invaluable in the process of

building homes and industrial buildings, particularly for the

refrigeration and air conditioning equipment installed. It also can

be used to make brake system lines in the automotive industry.

Tubing made from copper is one of the few naturally-sourced

materials that are 100% recyclable, so no metal is lost in

reclaiming copper from pipes no longer needed, making it a good

choice for the future.

| Product Name | 0.1mm-100mm Thickness H62 H65 H80 H90 Copper Pipe For Brake System Lines In The Automotive Industry |

| Material | Copper |

| Standard | ASTM, AISI, JIS, DIN, GB, EN |

| Grade | C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920,C10930, |

| C11000,C11300,C11400,C11500,C11600,C12000,C12200,C12300,C12500,C14200, | |

| C14420,C14500,C14510,C14520,C14530,C17200,C19200,C21000,C23000,C26000, | |

| C27000,C27400,C28000,C33000,C33200,C37000,C44300,C44400,C44500,C60800, | |

| C63020,C65500,C68700,C70400, C70620,C71000,C71500,C71520,C71640,C72200 | |

| T1,T2,T3,TU1,TU0,TU2,TP1,TP2,TAg0.1, | |

| Shape | Tube |

| Temper | O-H112; T3-T8; T351-T851 |

| Size | thickness: 0.3mm~100mm; OD:1-600mm; Length: 1000mm~12000mm |

| Surface | Mill finish, polished, anodizing, brushing, sand blasting, powder coating,etc |

| Payment terms | T/T, L/C, western union, Paypal |

| Price terms | CFR,FOB,CIF,Ex-work,CNF |

| Package | Standard export seaworthy package or as required. |

| Contact | If you have any question, please feel free to contact me. |

Our Advantages

1. We have more than 10 years of experience in copper pipe

production and complete testing equipment. The pipe's blasting

pressure, tensile strength and elongation are all above the

national standard. Ensure stable quality of ex-factory products and

meet the requirements of users under various natural conditions.

2. Through the strict control of the production process and mold

management, the wall thickness of the copper tube is ensured to be

more uniform, which makes it more resistant to pressure and more

durable.Copper tubes with uniform wall thickness can withstand

greater pressure, lower probability of blasting leakage, longer

service life, and customers have more choices of wall thickness.

3. Our copper tubes are all produced with high purity electrolytic

copper plate (purity more than 99.95%), with excellent surface

quality, no inclusion, trachoma, cracking and other phenomena,

eliminating the possibility of refrigerant leakage in these

defective places.

FAQ

Q1. Are you a manufacturer or trader?

We are a manufacturer, and we can have our own factory produced

many steel products.

Q2. Whether your company supports Trade Assurance order?

Yes , we can (100% product quality protection; 100% on-time

shipment protection; 100% payment protection)

Q3. Can we get the some samples? Any charges?

Yes, you can get available samples in our stock. If the samples

from new production, we will charge some reasonable cost, but this

amount will be deducted from your first order.

Q4. How do we build up business relations with your company?

Send us your requirement which includes size, coating info,

parameters, quantity, destination .

Q5. What is the MOQ?

We can accept small orders. Please feel free to contact us, we can

meet your requirements.

Q6. What's your advantage?

With high-quality products and efficient customer service, we

adhere to the principle of customer first.

Q7. How long is your delivery time?

Prompt or as your request.

Q8. What is your terms of payment ?

30%TT in advance and the balance against of copy of B/L.

|